Build cmms software for manufacturing, no code required

Optimize maintenance tasks, reduce downtime, and enhance efficiency with a custom CMMS solution tailored for your manufacturing operations.

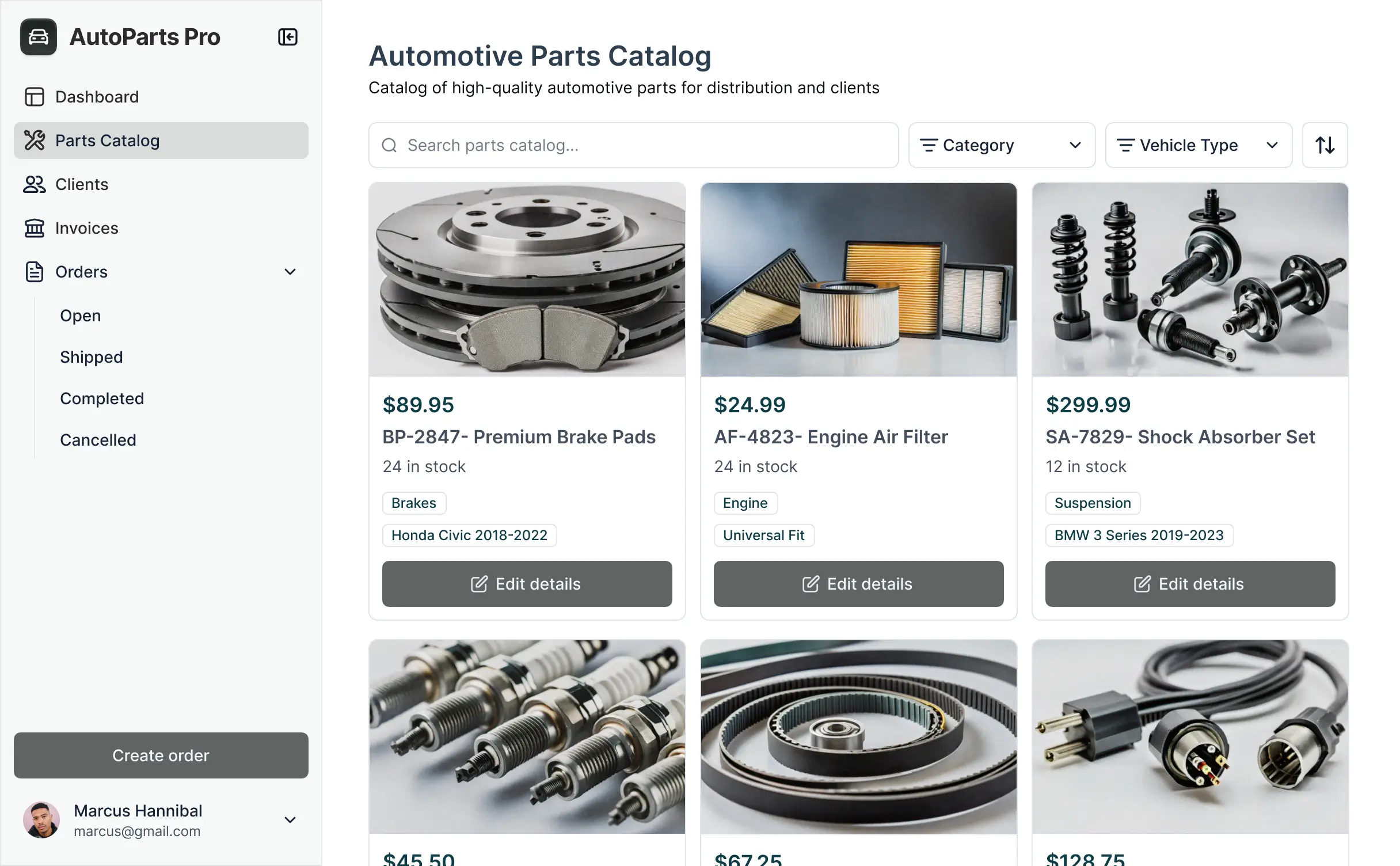

Customize your CMMS around your processes

Build a CMMS that matches your manufacturing workflows. Add only the views and features you need, and adapt your setup as requirements change.

Unify your maintenance data in real time

Connect spreadsheets, ERPs, and other systems with real-time sync—or manage everything in Softr Databases. Create a single source of truth for your maintenance workflows.

Custom access for every team. Built-in security, no dev time.

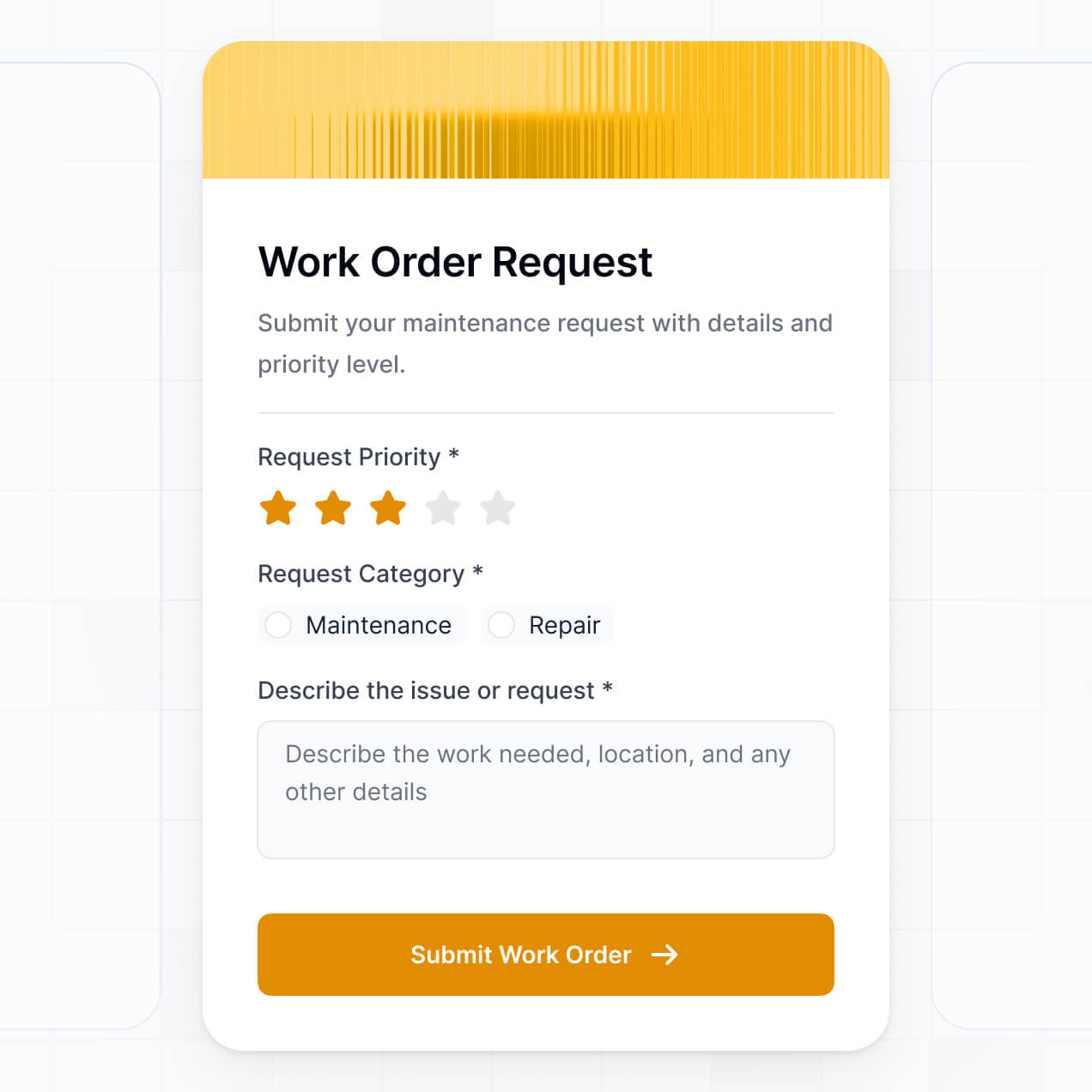

Give maintenance teams the right tools and access for managing manufacturing work orders. Set up secure logins, user groups, and permissions with ease.

Advanced permissions

Provide maintenance staff, engineers, and managers with dashboards and access tailored to their roles.

User groups

Provide maintenance staff, engineers, and managers with dashboards and access tailored to their roles.

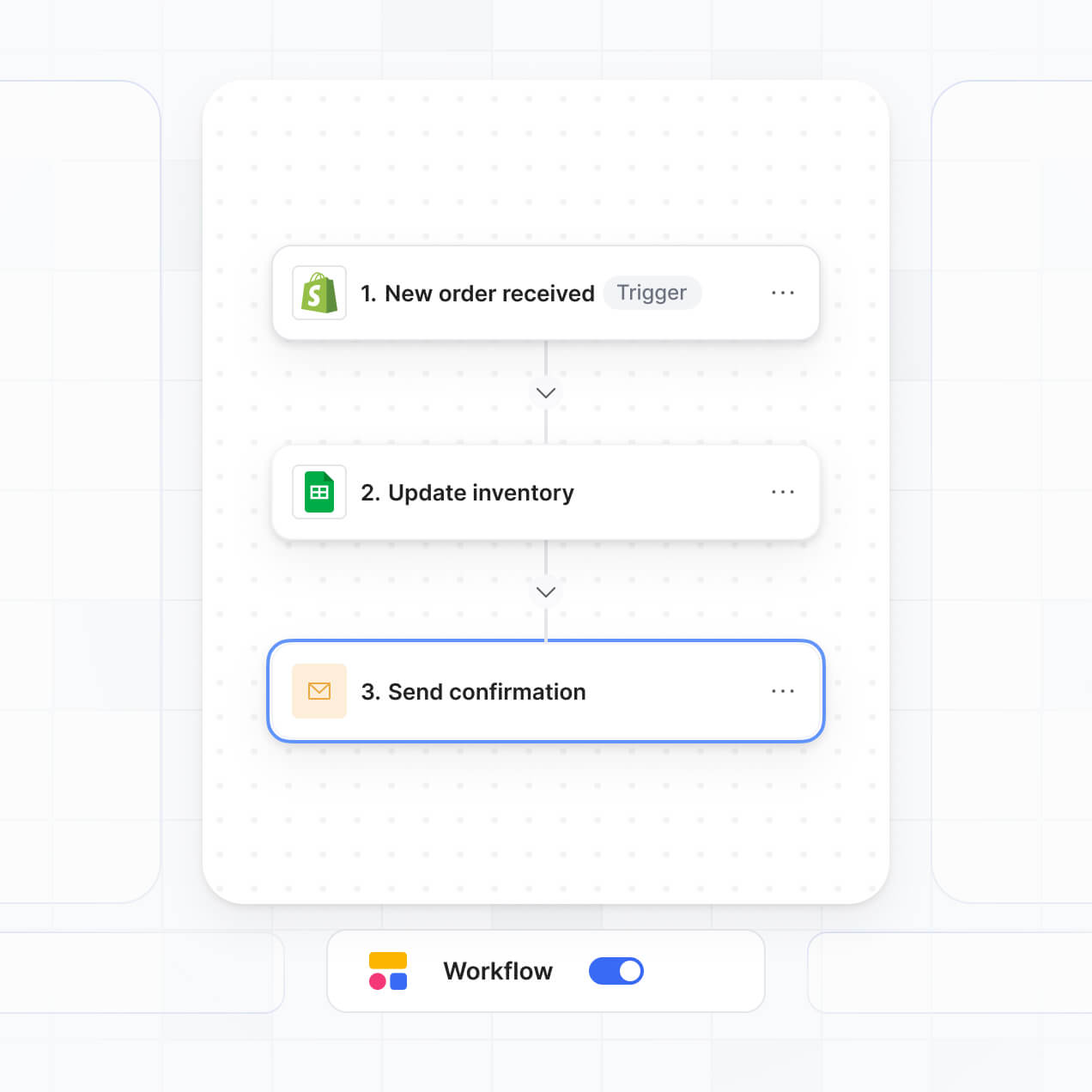

Automations

Integrate with existing tools to trigger alerts, automate task assignments, and streamline routine processes.

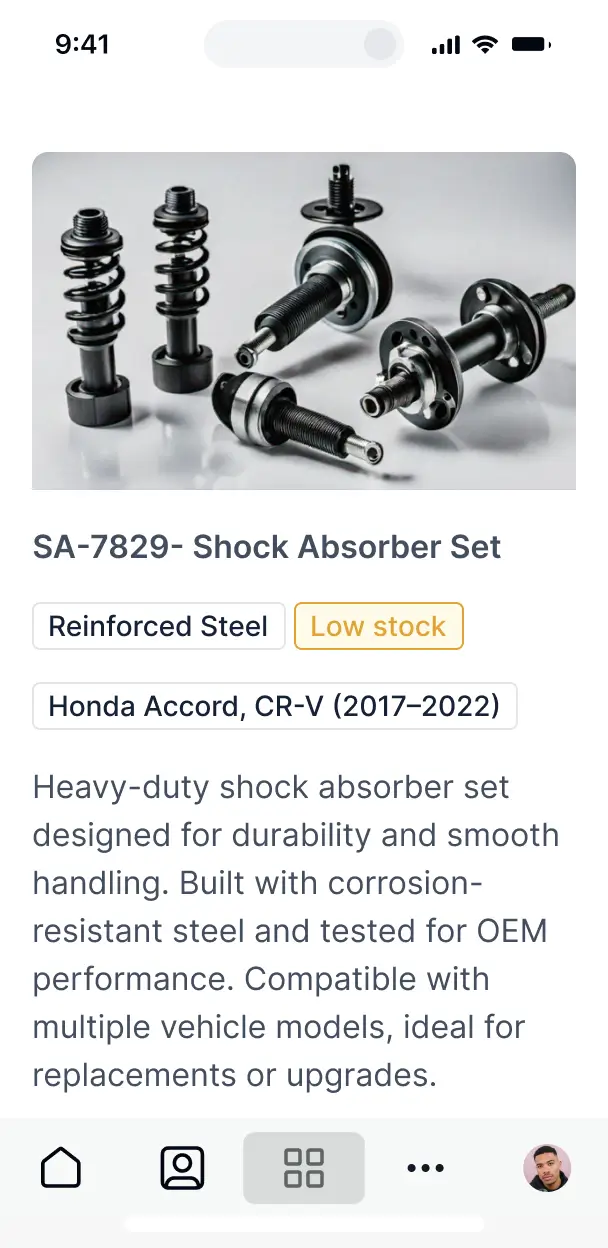

Works on any device

Access and manage work orders on the factory floor or on the go. All apps are mobile-ready out of the box.

Easy, secure logins

Let your team log in via email, Google, or SSO for quick, secure access—no IT help required.

Security

Keep sensitive maintenance and production data secure with SOC2 and GDPR compliance at every level.

.svg)

Give maintenance teams an AI helper

Teams can ask AI about work orders, schedules, or assets—get instant answers right inside your CMMS for manufacturing.

Why Softr vs other software

No more one-size-fits-all tools or costly custom builds. Softr is easy to use and fully customizable, so you can launch faster, adapt as you grow, and skip the complexity of traditional software.

Easy, fast setup

Spin up a work order management tool for your plant in minutes—no coding or IT help needed.

Consolidate your stack

Add asset tracking, maintenance logs, or approvals as your manufacturing needs change.

Flexible as you grow

Manage work orders, schedules, and reports in one place—with no extra logins or software.

Build a fully custom cmms software for manufacturing in minutes

Connect to your data in seconds

Integrate with your spreadsheets and databases, including Airtable, SQL, Hubspot, Google Sheets, Supabase, BigQuery, and more—in just a few clicks. Your data is always secure and in sync.

Customize layout and logic

Drag and drop customizable building blocks with various views and functionalities. Granular permissions allow you to control what data each user can access, and which actions they can take.

Publish and launch

Ship applications that your team will love in minutes or hours, instead of days or weeks. Deploy on both desktop and mobile.

250+

600+

Frequently asked questions

CMMS software for manufacturing is a dedicated platform where your maintenance team can manage assets, schedule equipment maintenance, track work orders, and monitor production downtime—all in one secure place. It centralizes communication and record-keeping, so you no longer have to rely on spreadsheets, emails, or paper logs. This makes it easy to stay organized, keep machines running smoothly, and ensure compliance across your facility.

Softr makes it simple to build CMMS software tailored to how your manufacturing operation works. You can connect your existing data—like maintenance logs in Airtable, equipment lists in Notion, or inventory in SQL—and set up a system where your team can log in, create work orders, update maintenance status, and track parts usage all in one place.

You don’t need to code anything. You can start with a template or build from scratch, customize layouts, set up user roles, and brand the platform to match your company. It’s fast to launch, easy to update as your processes evolve, and flexible enough to support small workshops or large-scale manufacturing plants. Everything stays organized and visible to the right people.

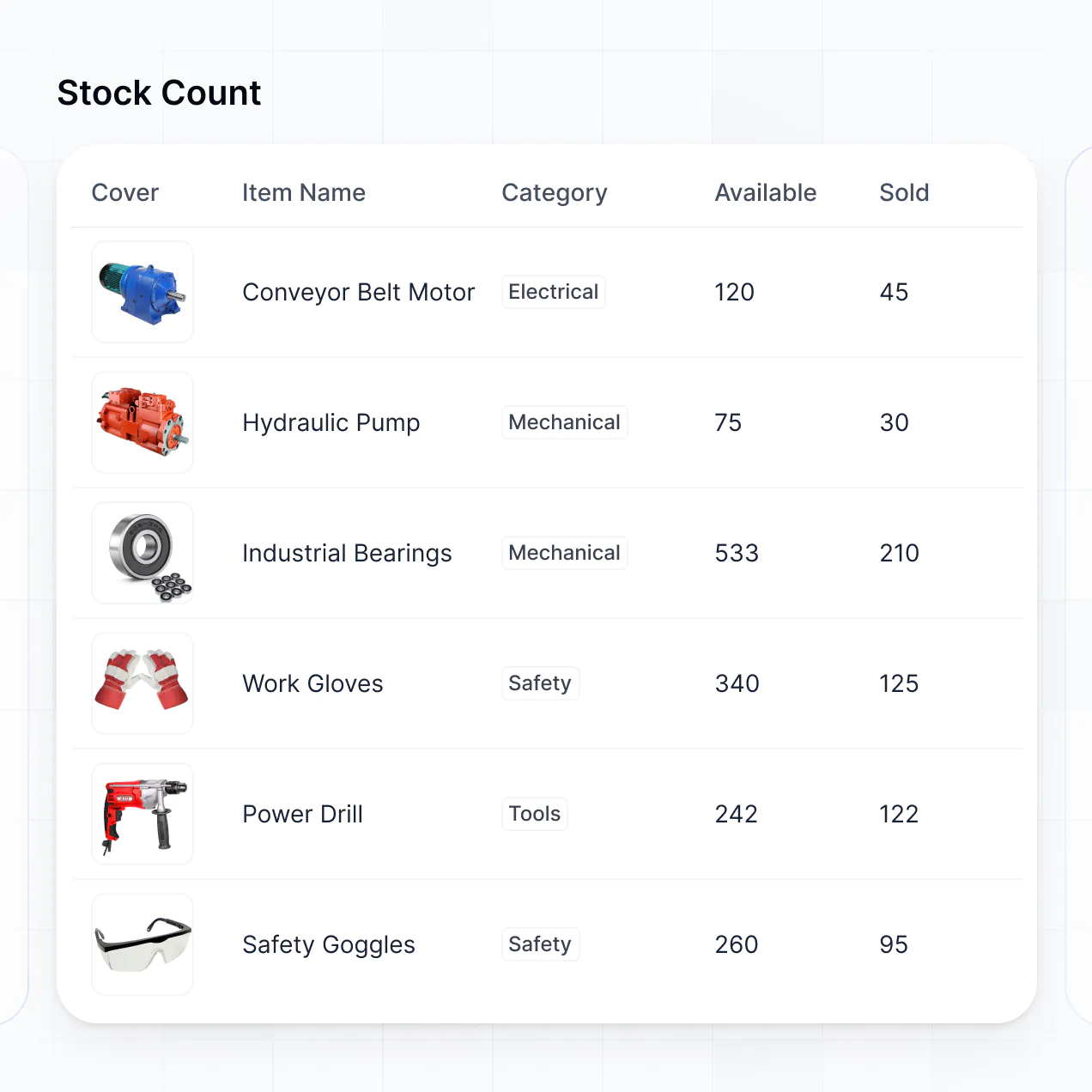

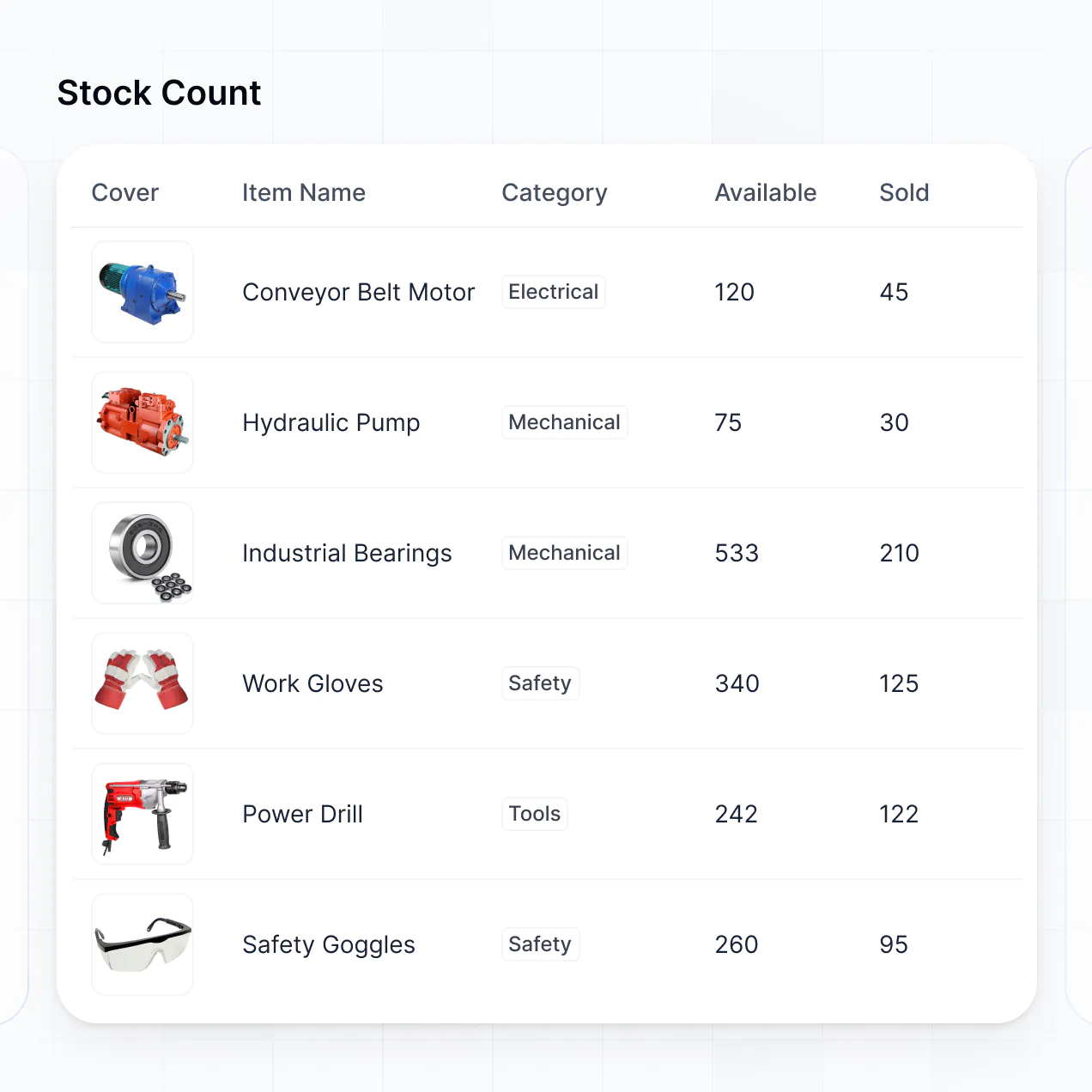

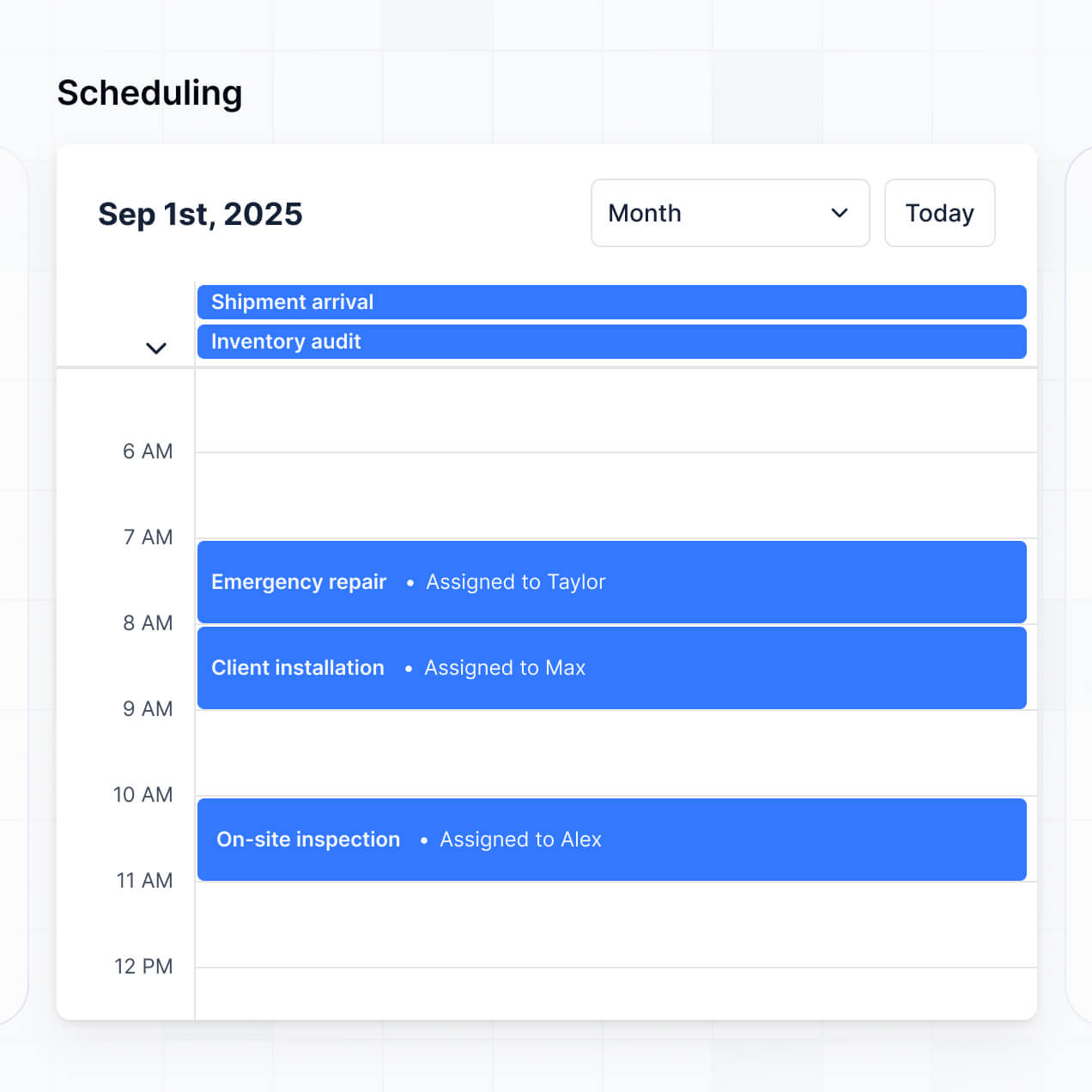

You can build a wide variety of features to fit your manufacturing maintenance workflow. Some of the most common include:

\- User logins – so each technician, manager, or supervisor can access their relevant information

\- Custom dashboards – to display work order statuses, equipment health, and maintenance KPIs

\- Work order forms – for submitting, assigning, and tracking maintenance requests

\- Asset management – to keep a detailed record of all machinery, tools, and equipment

\- Inventory tracking – to manage spare parts and supplies

\- Search and filters – to quickly find work orders, equipment, or parts

\- Tables, lists, and detail views – for maintenance logs, schedules, and compliance records

\- Real-time status updates – to keep everyone on the same page

\- Charts – to visualize maintenance trends, downtime, or costs

\- Calendar view – for scheduling preventive maintenance and tracking key dates

\- Permissions and roles – so each team member only sees what they need

All of this can be set up using Softr’s drag-and-drop blocks, so you don’t have to write code. And if your facility’s needs change, it’s easy to update your CMMS software anytime.

No coding is required. You can build your CMMS software for manufacturing entirely using Softr’s visual editor. Everything from the interface to user permissions is customizable without having to write a single line of code.

Yes. You can manage multiple maintenance teams, departments, or manufacturing plants within the same CMMS software. Each user only sees the work orders, assets, and data assigned to them based on their login and role. This is especially useful if your company operates across several facilities or manages maintenance for different production lines.

Softr supports a wide range of data sources for your CMMS software. You can connect to Airtable, Google Sheets, Notion, Coda, monday.com, HubSpot, Clickup, Xano, Supabase, PostgreSQL, MySQL, SQL Server, MariaDB, BigQuery, and more. You can also bring in maintenance data from other sources using the REST API.

You’re not limited to one source—integrate multiple databases into the same CMMS and display them together. For example, you could pull in asset data from Airtable and maintenance schedules from Google Sheets. Most sources support real-time, two-way sync, so your records stay up to date automatically.

Yes, Softr gives you full control over how users experience your CMMS software. You can tailor the layout, navigation, and content to match your company’s maintenance workflow. Each page or section can be shown or hidden based on the user’s login, so every maintenance technician or manager only sees information relevant to them.

You can also set up specific user roles such as technician, supervisor, or admin, with detailed permissions for viewing or editing data. For example, technicians might only see their assigned work orders, while supervisors can review all maintenance records. You can even create personalized dashboards or views based on the logged-in user.

This level of customization is especially helpful when managing maintenance for multiple teams, plants, or production areas in the same system. It keeps the experience secure, efficient, and tailored to each user’s needs.

Yes, you can. You don’t need to import data from another source to start building your CMMS with Softr. If you’re starting fresh, Softr Databases are built into the platform and integrate seamlessly with any maintenance management app you build.

If you do have existing data in tools like Airtable, Google Sheets, or other systems, you can connect those as well. The REST API connector also allows you to bring in maintenance data from other sources. Either way, you have full control over how your maintenance records and asset data are structured and displayed in your CMMS.

Yes, you can fully white-label your CMMS software for manufacturing in Softr. You can use your own company’s logo, brand colors, fonts, and even your custom domain to ensure the software looks and feels like an integrated part of your operations. All Softr branding can be removed, so your maintenance teams and staff only see your manufacturing company’s identity throughout the entire experience.

Absolutely. Softr offers extensive flexibility for customizing both the design and layout of your CMMS software for manufacturing. You can tailor colors, fonts, spacing, and the overall page structure to align with your manufacturing brand and workflows. Choose how each dashboard or module is arranged, configure which blocks are visible where, and control access for different user roles in your facility.

To present your maintenance data, you can use several types of blocks depending on your requirements:

\- Table blocks – to show structured data like work order lists, asset inventories, or maintenance schedules

\- List or Card blocks – to highlight equipment status, team assignments, or key resources

\- Detail View – to focus on specific records, like equipment profiles or individual work orders

\- Forms – to capture maintenance requests or inspections

\- Charts – to visualize maintenance KPIs or downtime trends

\- Calendar blocks – to track scheduled maintenance or production deadlines

If your design or process needs evolve, you can easily update and adjust everything directly in the visual builder.

Softr is designed with security as a top priority. All maintenance and operational data in your CMMS software for manufacturing is encrypted both in transit (TLS) and at rest. Your app is hosted on secure, reliable infrastructure, giving you comprehensive control over who can access and manage information. You can implement role-based permissions, manage users directly from your data source, set visibility rules, and apply global restrictions to safeguard sensitive plant or asset information.

For apps connecting to external sources like Airtable, Notion, or SQL, Softr does not store your data; instead, it displays data in real-time according to your access settings. You always remain in full control of who can view or modify maintenance data.

Softr also adheres to industry best practices around authentication, access control, and ongoing platform monitoring to keep your manufacturing data secure.

You can get started at no cost. Softr’s Free plan lets you publish one app for your CMMS software for manufacturing with up to 10 users and 2 user groups, and includes support for standard data sources like Softr Databases, Airtable, Google Sheets, and more.

If your maintenance solution needs to support more users or advanced features, you can explore Softr’s paid plans to scale up as your manufacturing operations grow: <http://softr.io/pricing>

Softr is built to help you quickly create fully functional, user-facing apps—like CMMS software for manufacturing, maintenance portals, and internal operational tools—without writing code or relying on IT. What makes it stand out is how rapidly you can go from a maintenance requirement to a working CMMS, and how well it integrates with your existing plant data sources.

Unlike no-code platforms focused on mobile development (like Glide) or that are more developer-centric (like Retool), Softr is designed for operations and maintenance teams that want easy control over layout, user access, and system workflows. You can build on top of live data from Airtable, Google Sheets, Softr Databases, or SQL, and create secure, branded apps tailored for your manufacturing teams.

You can visually customize everything—from dashboards to permissions. Plus, Softr’s built-in support for user roles, forms, conditional logic, and APIs means you don’t need to piece together multiple tools to launch a polished, effective CMMS solution.

Yes. Softr supports a wide range of integrations so your CMMS software for manufacturing can connect seamlessly to the rest of your maintenance and operations tech stack. Sync with tools like Slack for team notifications, connect with external databases, or automate maintenance workflows using Zapier, Make, and N8N. Softr also supports REST API and webhooks for more advanced, custom integrations.

Whether you want to push maintenance updates to another system, trigger work order automations, or display equipment data from other platforms, it’s all possible—no coding required.